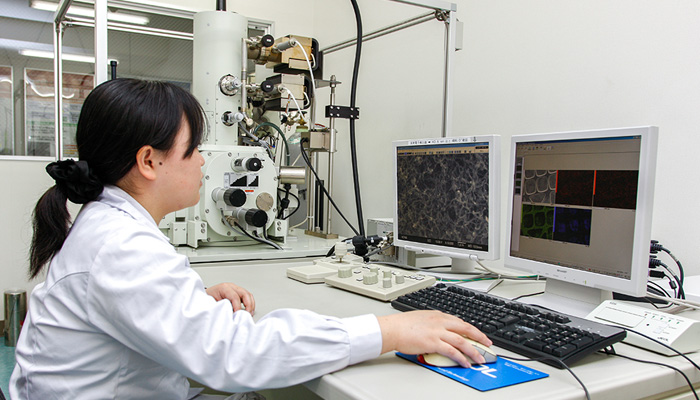

Analysis room/FE-SEM,Fluorescent X-ray analysis equipment

The structure of carbon nanotubes etc. is analyzed using a scanning electron microscope (FE-SEM). In addition, the minute amount of X-ray generated is analyzed using spectral analysis (EDS) and the results are then mapped using colours to analyze the composition of the chemical elements in the material.

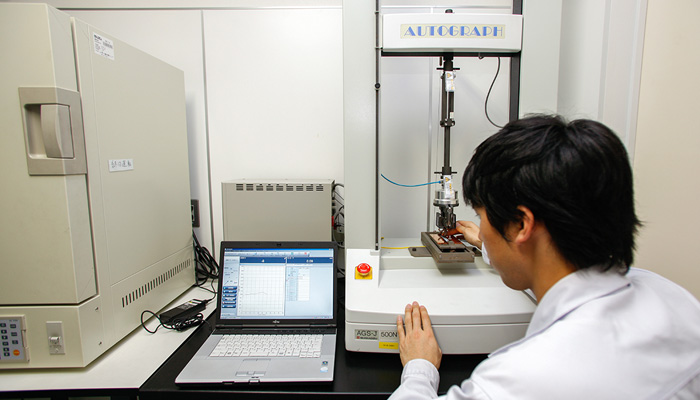

Evaluation room/Peeling test machine

Test machine for measuring the tensile strength of resin plating parts. A film layer with notches 10 mm in width cut into it is peeled with a test machine to investigate the strength. Data under various conditions can be obtained by coupling it to a PC.。

Evaluation room/Cold energy impact test machine

-This is a test to investigate the thermal impact on plated plastic products by subjecting them to temperatures of -30℃ and 80℃. Expansion, cracks and deformation of the plating which occur as a result of strains caused by the difference in the thermal expansion coefficients of the substrate and plating layer can be checked.

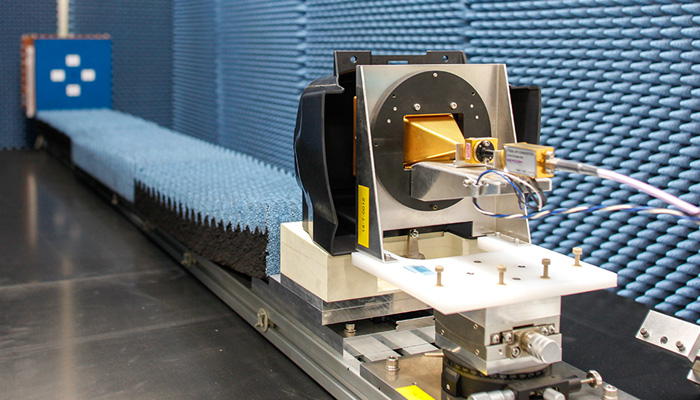

Evaluation room/Milli-wave measurement instrument

This is a system to test the permeability of the emblem against millimetre waves. Millimeter waves are radiated from the rear of the emblem of the front grille and then the reflected waves are measured.

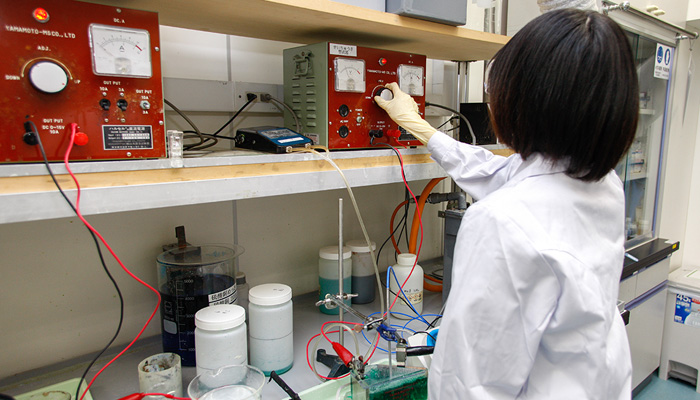

Analysis room / atomic absorption photometer

Measure the metallic elements in a specimen by measuring the absorption spectrum when a liquid specimen is heated to a high temperature, atomized and then illuminated with light. With its ability to analyze even minute quantities of metallic elements, this system is mainly used to control the plating baths in our company.

Analysis room / Halsell test

This test investigates the deposition condition of the plating for each current density using a trapezoidal water tank where the distance between the electrodes is constantly changing. Since the plating baths in the factories are constantly changing, this is a crucial task in controlling this condition qualitatively.

Research room / Test plating facility

When performing plating during the mass production process in the factory, verification at the experimental level is required. The deposition speed of the plating and data on the film condition is obtained by adjusting the immersion time, concentration and component ration of the substances included in the plating solution.

Deposition room / vacuum deposition equipment

Manufacturing equipment with dry plating function corresponding to millimetre wave radar. A thin, uniform plating film at nano-level can be formed through vacuum deposition.

Research room / i-Coat*

A special surface treatment with a metallic surface lustre called i-COAT* that is currently being adopted for mass production. By introducing cracks at the nano-level, we expect this process to be commercialized as a ground-breaking technique in place of sputtering and vacuum deposition with optical and electromagnetic permeability while remaining thin, lightweight and flexible.

*i-Coat is currently trademark pending.

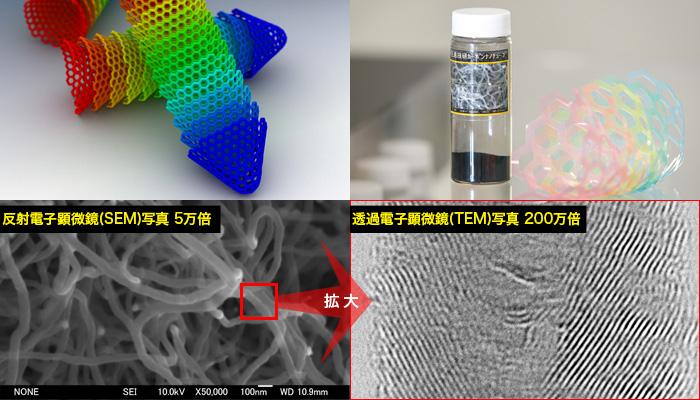

Cup stack-type carbon nanotube

High in strength, flexibility, thermal conductivity and electrical conductivity, carbon nanotube (CNT) is a material that is attracting much attention. Our company possesses technologies that are capable of manufacturing and dispersing this as a powder. Furthermore, our company’s CNT has a unique structure known as a cup which has excellent absorption capability.