-

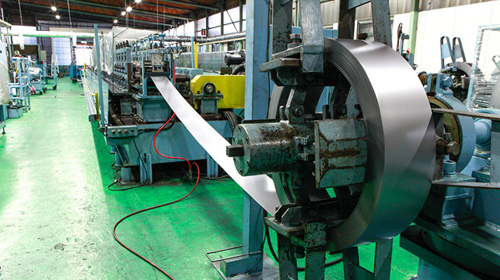

Multi-stage Roll Forming

Major Product Applications

Using up to 60 rolling stages, we fabricate products with complex cross-sectional shapes, such as automotive door-frames. In addition to roll forming, we perform the subsequent operations of welding, bending, and cutting in a consistent process.

-

Sankei forms high-quality stainless steel pipe by utilizing our proprietary technologies and manufacturing equipment developed in-house. We continuously strive to enhance material yields by linking this equipment to precision-operated cutters so that the exact lengths to be used are cut. Typical sizes: Wall Thickness (t) of 0.3~0.4mm, Outer Diameter (O.D., φ) of 50~90mm.

-

General-purpose Pipe Forming

Sankei achieves consistent quality control using cutting-edge roll-forming equipment and laser welding. Compared to welding methods such as induction or TIG welding, the areas affected by heat in laser welding are small, and post-processing workability is superior.

-

Spin Forming

Major Product Applications

Spin forming, also known as metal spinning, is a fabrication method in which stainless steel and other sheet metals or pipe-shaped products are clamped or spun while being pressed by rollers and formed into shapes. This technique is used to make a wide range of products, from automobile exhaust parts to ordinary household items like vacuum flasks.