-

Major Product Applications

Tight radius bending involves bending metal with a small or minimal radius (R). This technology enables tight bends that would be impossible with a standard rotary bender. Since the elongation distances of the inner and outer surfaces differ greatly, problems such as cracks, fractures, warping, and creasing would occur with conventional techniques. But with our tight radius bending technique, these problems are resolved by maintaining a uniform wall thickness. An inside bend radius as little as 5mm (R5) may be specified for products from Sankei.

-

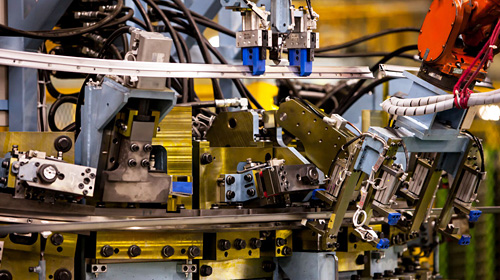

These machines perform bending of cold-rolled parts such as door sashes and moldings. They pull both ends of the material while performing numerical controlled shaping to progressively bend the part by compressing it onto the die. Sankei achieves high-precision bends with its original stretch benders.

-

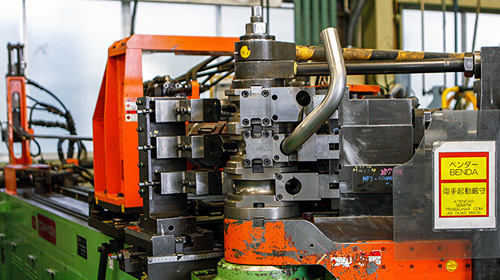

Rotary Bender

Rotary benders are machines that bend straight pipes (with round or square cross sections) progressively along a set metal channel. They can also be used to produce complex bent shapes with numerical control (NC). Sankei has a proprietary technology for bending double walled pipes maintaining an air gap between the inside and outside pipes. This is used for producing automobile mufflers and dishwasher drainage and supply pipes.

-

NC Press Brake

Major Product Applications

These machines perform bending of sheet metal. Using numerical control, the settings for sheet thickness, bending radius, bending angle, etc. are input, and high-precision bending operations are possible. Such equipment can achieve both high productivity and high quality, which is sought after for diversified small-lot production.