-

An original, functional-coating product, i-Coat* represents the forefront of our company's surface-treatment technologies. In appearance, it has the same metallic sheen as an ordinary metal plating. However, after imparting tiny nano-level cracks to the surface, it maintains a thin, light, and flexible quality that is and is semi-transparent to light (translucent) and also to electrical waves. It is expected that this revolutionary processing method can be utilized in place of sputtering or vacuum deposition.

*i-Coat is currently trademark pending. -

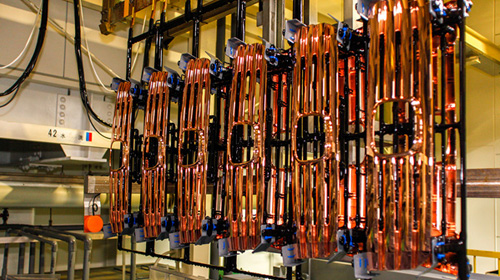

Metal Plating

Combining ornamental chrome plating of steel with triple-nickel and micro-porous chrome plating, our metal plating has an extremely high resistance to corrosion. It can be used for many applications, from items such as steel automotive bumpers to large-scale plated products.

-

Sankei performs a range of plastic plating, from ornamental chrome plating of ABS (acrylonitrile butadiene styrene), polycarbonate/ABS, and polypropylene, to large-scale plastic plating. Combining triple-nickel and microporous chrome plating, our company's plating has an extremely high resistance to corrosion. Moreover, only Sankei is able to perform industrial plating of polypropylene.

-

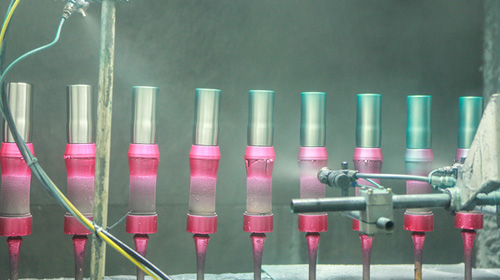

Heat-resistant Metal Painting

Sankei has developed and applies a special paint for mufflers, which are subject to constant high temperatures. This paint can withstand 650°C.

-

Sankei performs metal painting of many types, from general-purpose metal painting to colorful paints used on vacuum flasks and for food safety markings.

-

Sankei can perform large-item plastic painting, such as automobile Bumper Cover, using many color variations including pearl-white.

-

Sankei performs cationic electrodeposition painting of steel and galvanized steel plate. Cationic electrodeposition painting possesses a high resistance to corrosion well suited to automotive suspension parts, and can also be used for coating metal parts with complex shapes.