Since its establishment in 1948, Sankei has built upon its foundation in metal plating to expand its operations along with the prosperity of the automobile industry. Once we succeeded in incorporating die-making know-how in pursuit of higher yields, we expanded our areas of technical expertise to the upstream process of metal forming. We then ventured further into the molding of plastic resins and surface treatment. Now, by a technological fusion that we represent by the "formula" (Metals + Plastics) × (Forming + Surface Treatment), Sankei is taking on new technical challenges to respond to new needs.

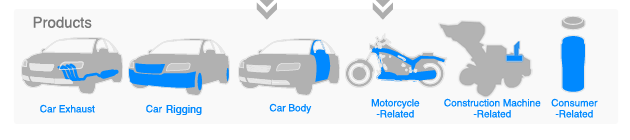

For example, by means of a new manufacturing technique, Sankei has been developing a thin-wall pipe forming process that achieves a vast improvement in material loss. We are also developing plastic parts that have island plating transparent to electromagnetic and light waves, and with the appearance of metal. We have also branched out into the design and fabrication of assemblies with plastic and metal parts, and using the technologies we developed in our automobile and motorcycle operations as well as our diversified small-lot production know-how, we have expanded into construction and cooking equipment. In these ways, we continue to pioneer in advanced technologies and yet-unknown product fields based on our core technologies.

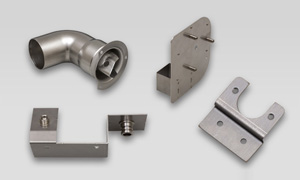

Thin-wall pipe forming line (Ano Factory)

Laser/Punch Combination Machine (Toda Factory)

Tsuzumi Bottle that achieve a beautiful appearance

High-precision bending of products done by a NC press brake